Applicable Industries:

Hotels, Machinery Repair Shops, Manufacturing Plant, Restaurant, Food Shop, Food & Beverage Shops

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

Motor

Condition:

New

Place of Origin:

Guangdong, China

Brand Name:

Linkrich

Voltage:

380, 380V

Weight:

750

Dimension(L*W*H):

2300*1780

Year:

2020

Warranty:

1 Year

Key Selling Points:

High Productivity

Item Name:

tunnel oven

Power Source

Electrical

Wattage:

120W

Temperature:

20~400°C

Net Weight:

750 kgs/per CBM

Packing:

Plywood

Dimensions:

2300*1780mm

Material:

Stainless steel

After Warranty Service:

Online support

Local Service Location:

None

After-sales Service Provided:

Online support

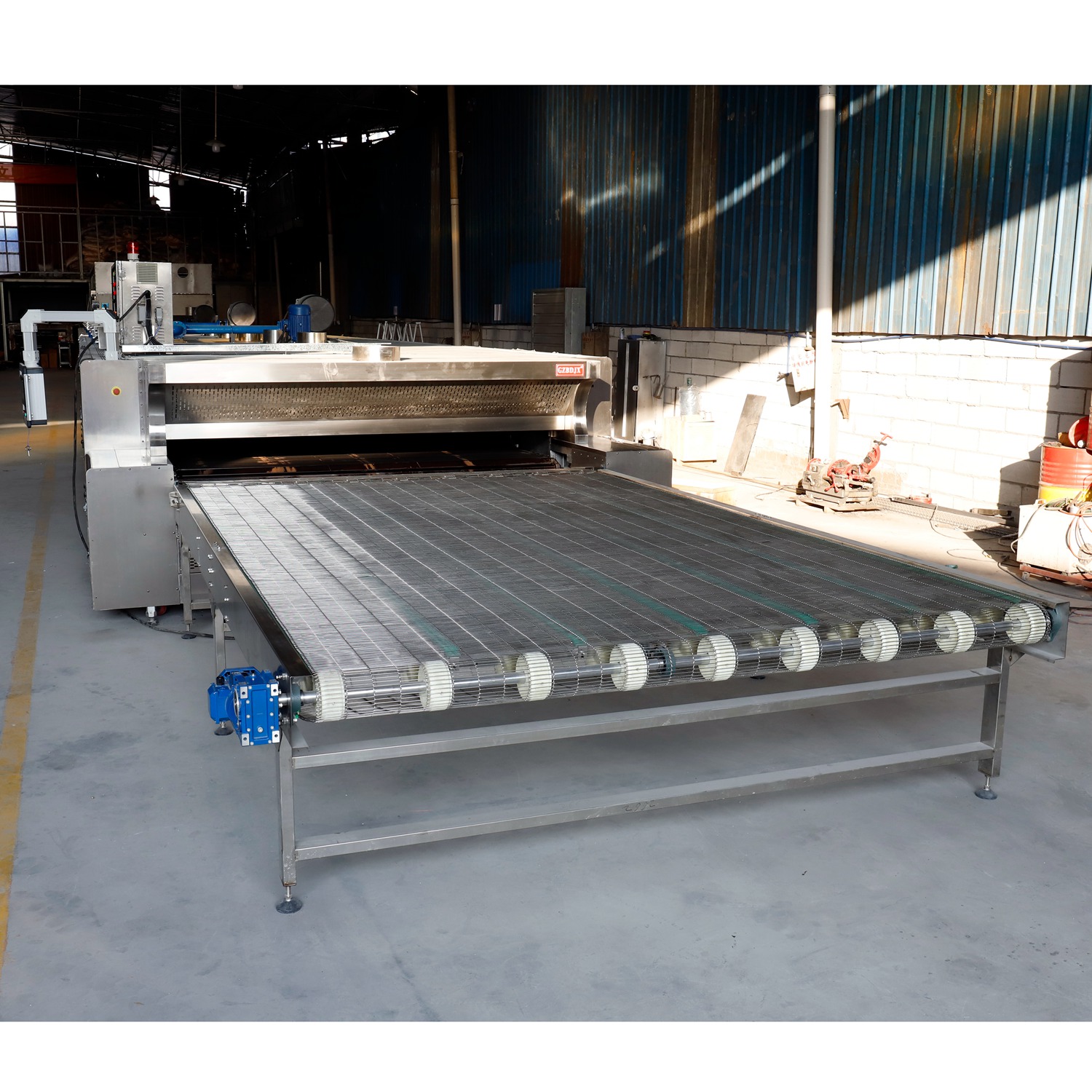

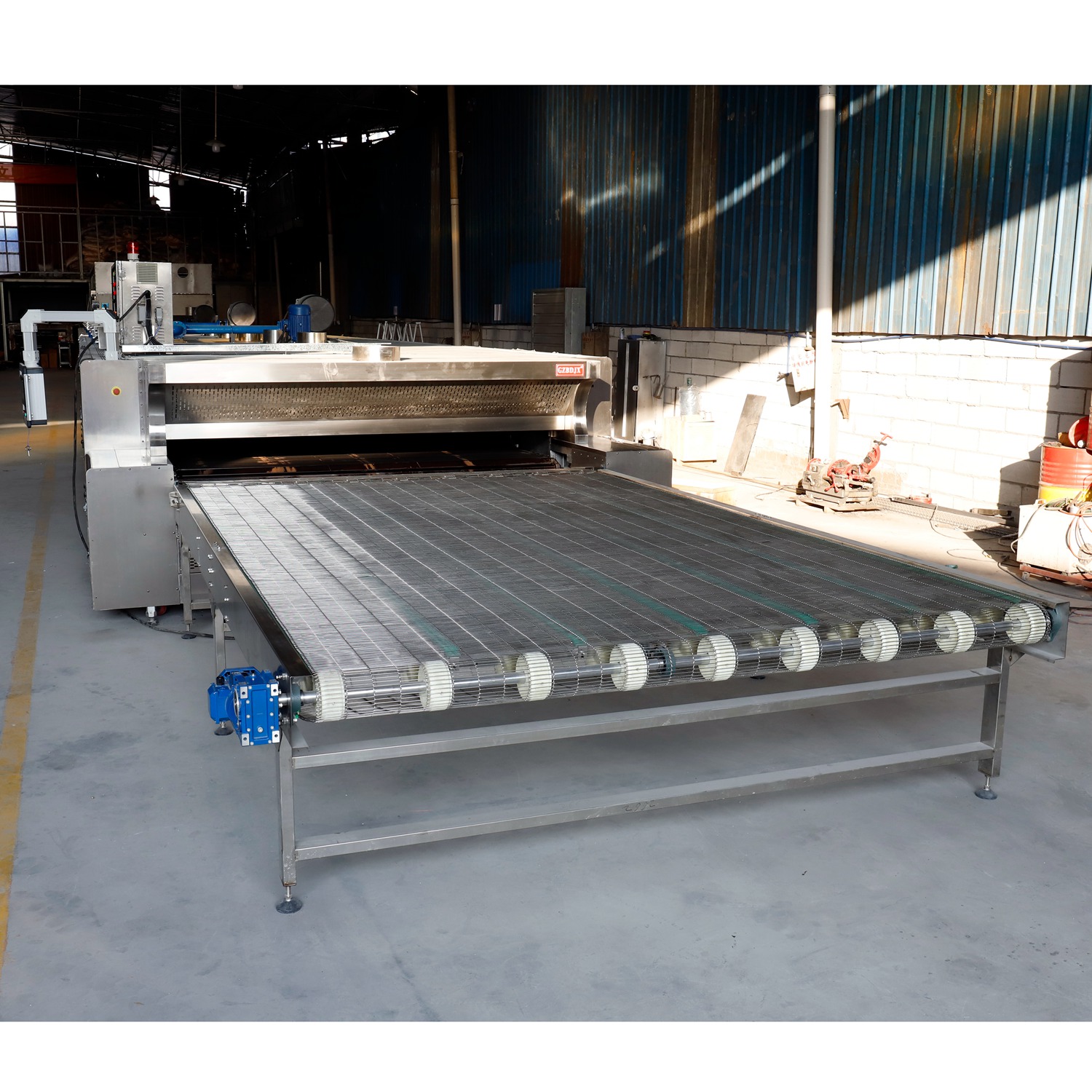

Electrical commercial Industrial drying tunnel oven burners for bread

| Model | Specifications | Trays(mm) | Voltage(V) | Power(kw/m) | Length(Custom made) (mm) | N.W.(Kgs/Per CBM) |

| LR-GS-T | 2 Trays 1.4M | 400*600 | 380 | 0.2 | 1400*2300*1780 | 750 |

| | 3 Trays 2.0M | 400*600 | 380 | 0.2 | 2000*2300*1780 | 750 |

| | 4 Trays 2.6M | 400*600 | 380 | 0.2 | 2600*2300*1780 | 750 |

1.Accesories such as igniter are manufactured in Japan, and PLC control is manufactured by Siemens.

2. Each tunnel furnace is customized according to the bread and capacity

3. Each tunnel oven has 3 temperature control areas:

-Entering the heating in the zone

-Intermediate baking area

-Each zone has thermostat.

4. For gas tunnel furnace, each burner can be opened or closed during other burners working .

The total heat output can be changed according to the product requirements.

5. Setting and indication are completed on PLC Monitor, including

-Baking temperature at top and bottom in the third zone

-Baking time